Interview: Wire race bearings for innovative exoskeletons

Mr. Wanner, how did this research project come about?

Johannes Wanner: In view of demographic change and the increasing lack of skilled workers, it is a major challenge for the economy to keep employees as long and healthy as possible in the work process. Explicitly, physically strenuous work that strains muscles, bones and joints must be considered here. Exoskeletons can help here. They are already used for heavy loads or unfavorable postures. Think of warehouse workers, painters, plasterers or assembly line workers.

Who are the people involved in the development?

Research institutes such as the TU Ilmenau or the University Hospital Jena support our work at Aalen University. Supporters of the project include Franke, companies from the orthopaedic technology sector and manufacturers of complex turned parts.

What is the challenge with the development?

The exoskeleton must not be perceived as irritating, the feeling of support must predominate. Since the „machine“ is attached directly to a human being, a good interaction must be created. The systems must complement each other. In addition, there are requirements regarding accuracy of fit, weight, safety and reliability. The system should be safe, robust and efficient. We need a lot of torque from little power. So far, there is nothing comparable on the market that actively supports people in various activities.

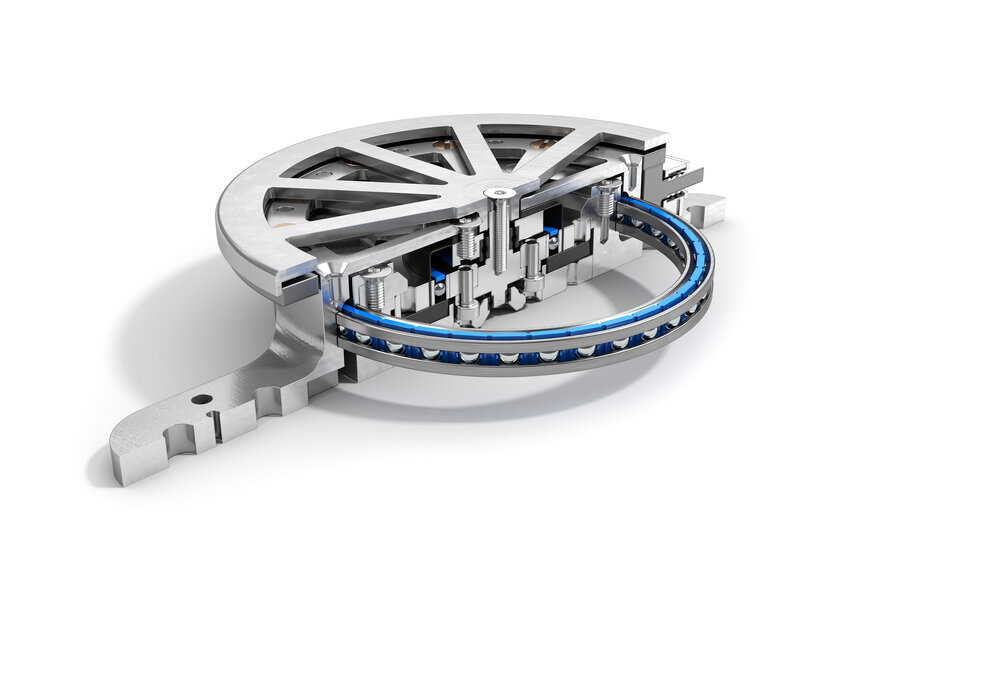

How can Franke wire race bearings support you?

Wire race bearings are very compact and lightweight. Especially the types of the LER series stand out. Simple mounting and adjustment of the preload are added. The center clearance of the bearing allows the gear unit to be centrally located. The large outer diameter ensures high rigidity.

What are the main criteria the joints have to meet?

The main criteria are stiffness, smoothness and load capacity. Low wear and tear is important, as well as smooth running and safety against damage, e.g. due to overloading.

How are the motors supplied with energy and controlled?

We calculate an energy requirement of 60 Watt per joint for 8 hours of use. This is easily achieved by modern rechargeable batteries. For stationary workplaces, a cable solution could even be considered. The sensors are controlled via the muscle. There should be no control buttons or similar. The sensors detect the muscle movement and a control unit determines the necessary rotation of the motor. This increases the ease of operation, but also raises the demands on the response of the motors and the load behavior. Absolute freedom of play is a basic requirement for the system. This is where Franke wire race bearings score points over other solutions due to the adjustable preload.

What are the advantages over existing systems?

There is not much on the market yet. Most of them work with knob or lever control and are also not modularly adaptable to different activities. Our system can do that better.

What are your expectations for the future?

Exoskeletons will become lighter and cheaper. The most important thing is the acceptance. The more they are used, the lower the inhibition threshold will be. We would like to see a boom similar to that of the e-bike. There, the leap from rehab to sports equipment has been successfully made.